I've spent 18 years watching energy and water retailers grapple with the same operational nightmare: systems that don't talk to each other, data flows that just don’t line up, and back-office processes that cost a fortune to run.

The frustrating part is that most of these problems are entirely solvable.

What's changed is that the technology has finally caught up with the ambition. More importantly, it's now mature enough to deploy without the usual horror stories.

In this article, we’ll share how leading utilities are using AI and automation to tackle long-standing operational challenges, from cutting costs and reducing failure demand to freeing up teams to focus on higher-value work. We’ll also show you how to take practical, low-risk steps to get started.

The long road from Excel

Back in 2014, I was still drawing process maps on brown paper and whiteboards, trying to figure out why customer bills weren’t being issued on time. The usual suspects were always there: read misalignment, CRM standing data not lining up with industry data such as Ecoes/Xoserve or CMOS, read windows not opening, or blocks and locks added and never removed.

My solution then was brutally simple: dump everything into one database, build a rules engine that could spot trouble, and hope for the best. It worked, sort of. Resolution times improved, costs came down a bit, and compliance teams could panic a little less.

The real breakthrough came with Robotic Process Automation (RPA). Once we could identify the repetitive fixes, we could automate them. Suddenly, the same team that was drowning in manual corrections could focus on the genuinely complex stuff. The business case wrote itself.

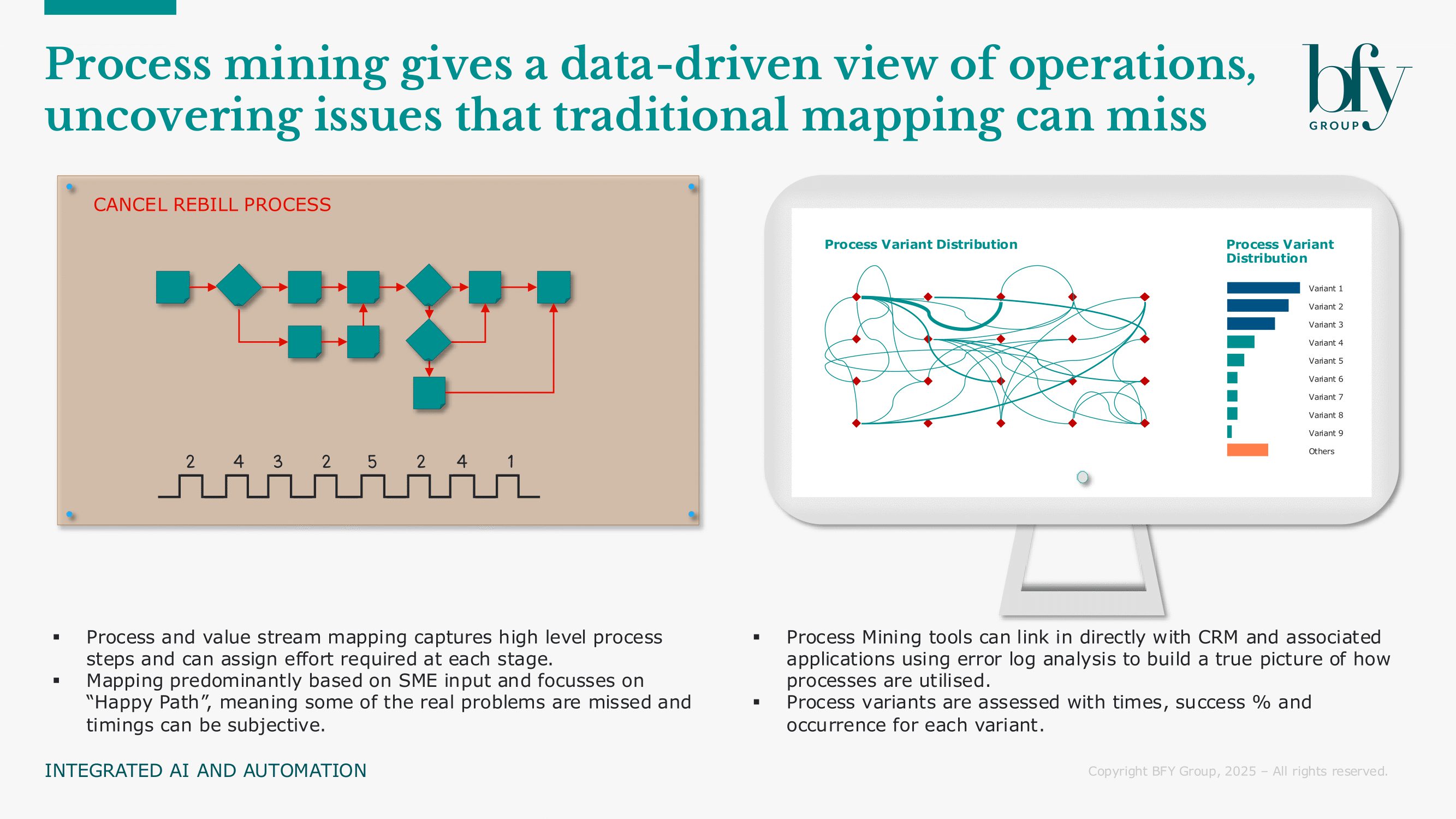

When process mining changed everything

Working with a process mining tech company was an eye-opener. Instead of me guessing where things went wrong, their process mining just showed me. Every variant, every dead end, every time-wasting loop- all laid bare from the system logs.

But what really mattered was it showed us the cost of each failure. When you can see that an incorrect meter reading costs £47 in operational effort, suddenly everyone cares about fixing it upstream.

The best part was the "human in the loop" automation. Systems that could spot problems developing and either fix them automatically or flag them to the right person immediately. No more issues festering in queues for weeks, or worse, hearing about the issue for the first time from a customer.

AI is more than a buzzword

The latest wave of AI tools, including real agential AI and Retrieval Augmented Generation (RAG) systems feels different. These aren't chatbots with delusions of grandeur. They can actually:

- Make sense of the chaos in your email systems and call logs

- Pull real-time data from across your entire operation as well as other, external sources

- Handle complete workflows without constant handholding

- Learn from their mistakes (revolutionary, I know)

What's really encouraging is that operations teams can now build these solutions themselves. No more waiting six months for IT to maybe understand your requirements, and no change request/procurement process every time you need to update or refine your solution.

The business case is compelling

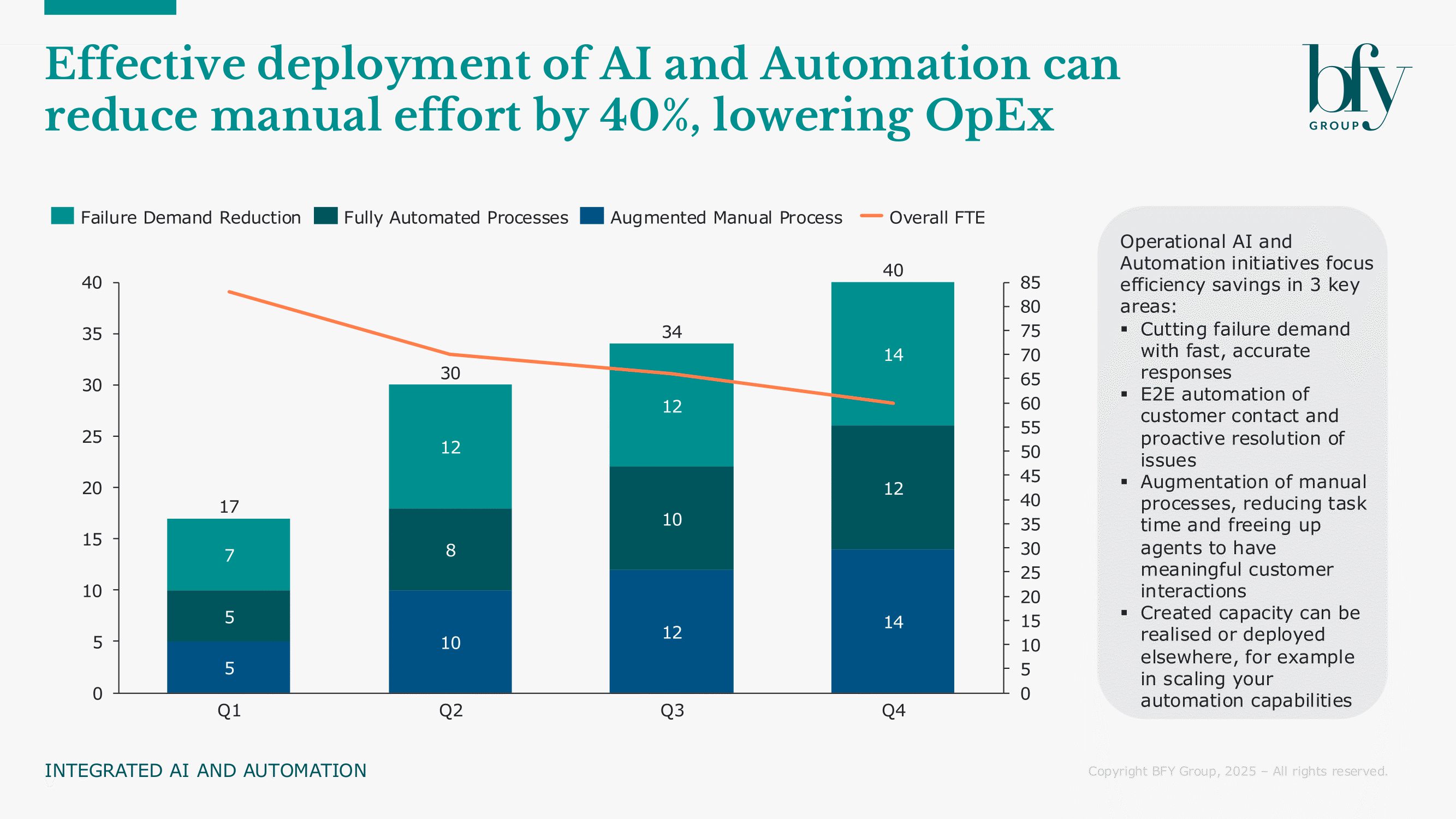

I've seen the numbers. Done properly, smart automation delivers:

- OpEx reductions of 20-30% in back-office functions

- Customer resolution times cut in half

- Failure demand down by 40%+ (fewer repeat contacts, fewer escalations)

- Staff who enjoy their jobs again

With price caps squeezing margins and customers expecting Amazon-level service, these aren't nice-to-haves anymore.

There are real risks

I've also seen implementations go spectacularly wrong. Automation that breaks industry codes because it doesn't understand the nuances. Solutions built in isolation that make the fragmentation worse. AI decisions that are so opaque that when things go wrong, nobody knows why.

Customers do not forgive "the AI did it" as an excuse, nor do industry regulators.

Making your organisational design work for you

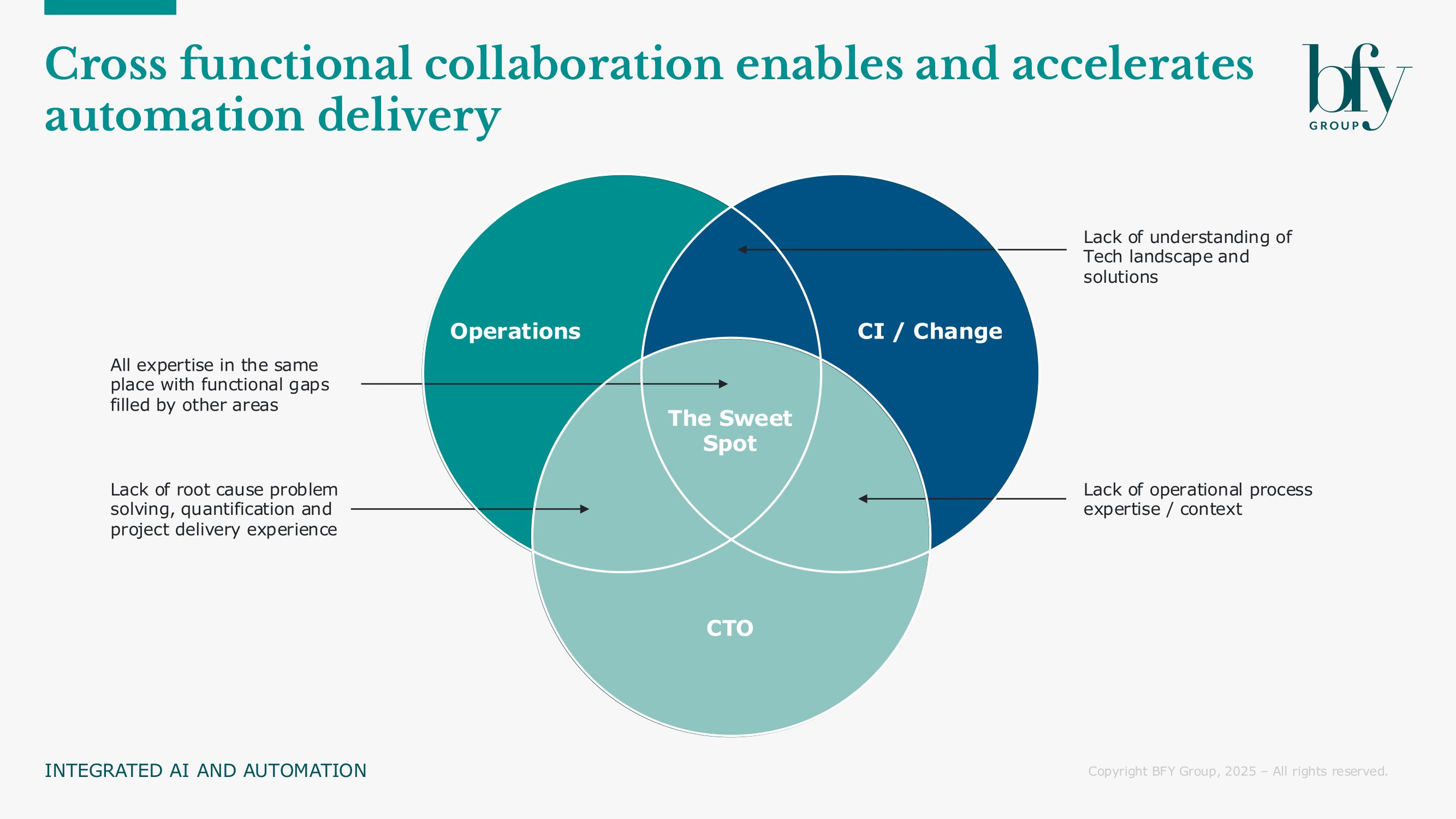

The challenge isn't just technical, it's organisational. I've worked across Operations, CI/Business Change, and IT, and each speaks a completely different language.

The Operations Perspective: If you're in Ops, you probably have a solid handle on what's breaking and why your customers are frustrated. You've got the process expertise and know exactly where the pain points are. What you might not have is the root cause fully figured out, the impact properly quantified, or the full picture on technical solutions.

The IT Reality: Your CTO and IT teams know the tools inside and out. They understand how they work together, what fits your architecture, what aligns with the roadmap and where economies of scale can play a role with tech vendors. However, it’s unlikely that they grasp the scale or real impact of what Operations deals with daily or how operational processes work.

The CI Gap: Business Change teams excel at root cause analysis and impact quantification but often lack the detailed process understanding to recommend the most effective solutions.

The Bridge You Need: This is why having someone who can speak all these languages matters. Someone with decades of utilities experience who's actually deployed these solutions and can break down the barriers between departments.

The pragmatic path forward

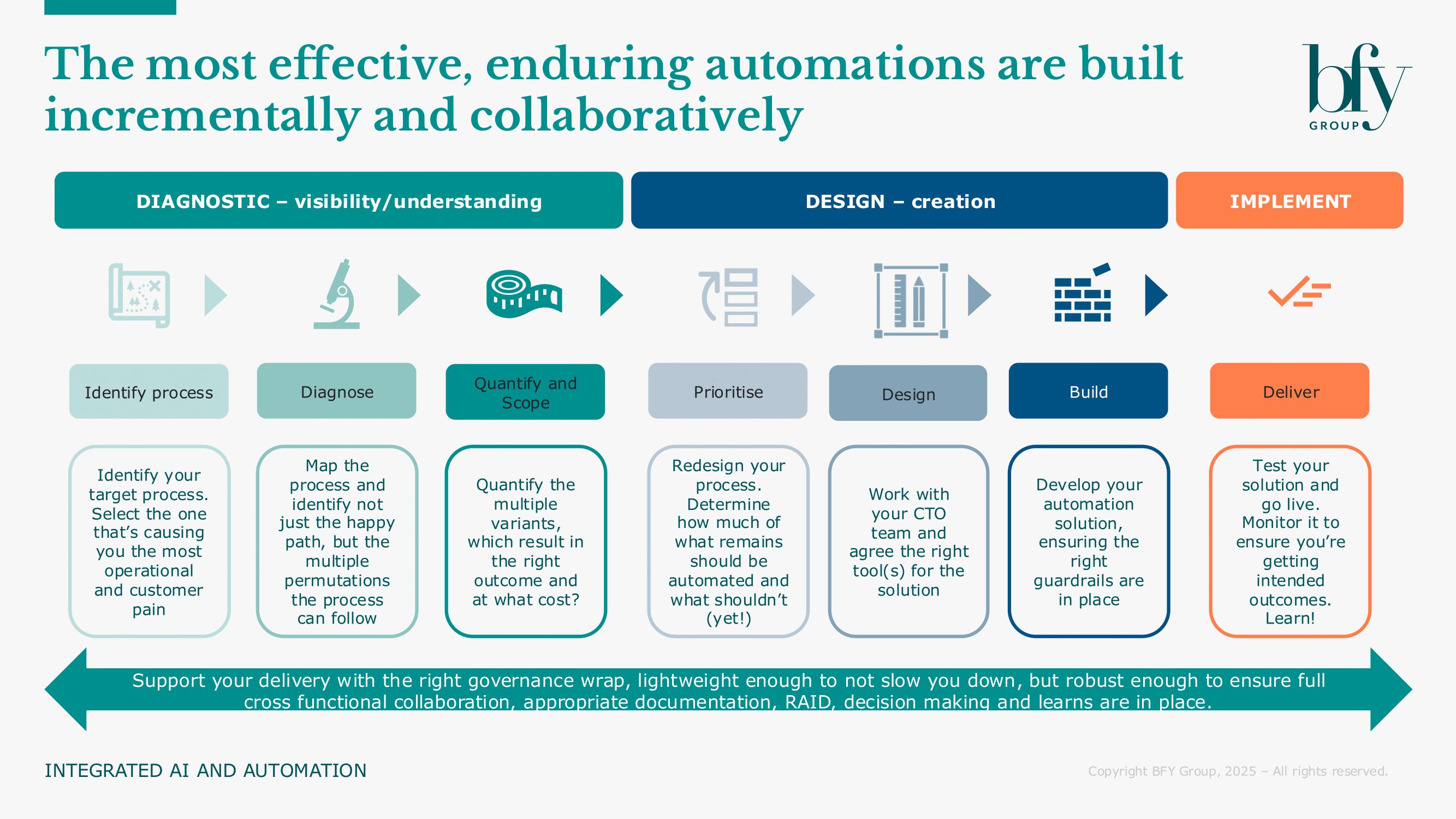

If you're an operations leader looking at this landscape, here's my advice:

Your end goal may be a fully integrated E2E solution that starts with controls and ends in automated actions, held together with intelligent workflow routing. But your build should be iterative, starting small and linking in more complex pieces of the system as you grow in capability and confidence.

Start with your biggest operational pain point, the one that costs you sleep and budget. Work with your CI teams to quantify the impact of the issue so you have a solid case for change. Map the impacted process properly, understand where it breaks and why. Redesign your process, take out the dead ends, the recurring loops and the over processing.

You’ll likely see substantial gains by doing this, in some cases this can be so impactful, your case for automation can decrease significantly. Once this has been done you can think about if you need a technology solution and if so, what that might be.

Before you start automating your process, figure out how you will feed your automation. You need to have a view on:

- How will your automation get the work?

- What will it do with the work item once it’s completed?

- Will it require a customer communication or will an agent need to take further action?

There are lots of ways you can address these areas, including using automated solutions to help, but when you’re starting out, keeping a “human in the loop” to guide these automations is a great approach. You can build in automated steps either side of the actual process as your capability grows.

Build in industry expertise from day one. These systems need to understand not just your internal processes, but how they connect to industry obligations and regulatory requirements.

Ensure you have the right CTO / IT colleagues on the pitch. Don’t start a procurement process or start downloading new tools without a solid conversation with the experts. Your business may already have access to appropriate tooling within the tech estate (many Microsoft houses can access co-pilot and the Microsoft Power suite for example) which may help speed things up. Digital safety is important and your CTO/CIO/CISO will be able to help you with the right advice to keep you safe.

What this actually means

The tools exist today to solve problems that have frustrated utilities for decades and are being used by many businesses within and outside of the utilities sector. With the ever increasing cost and regulatory pressure on utilities, well executed AI and Automation strategies are arguably the most impactful tools at your disposal to optimise both your operating costs are customer experience.

Success requires more than buying the latest AI platform, it needs strategic thinking, industry expertise, and a clear view of what good looks like for your customers and your operations.

The suppliers who get this right won't only cut costs, they'll build operational capabilities that their competitors can't match.

Ready to move past operational fire-fighting?

If you're tired of the same operational headaches eating your budget and frustrating your customers, we can help. At BFY, we've supported leading energy and water suppliers with cutting through the AI hype, and building automation strategies that actually work.

Rather than recommending tools, we help you choose the right approach for your specific challenges, guide you through implementation without the usual pitfalls, and set up your teams to keep developing these capabilities independently.

Whether you're drowning in exceptions, wrestling with late bills, or just want to free your operations team from the soul-crushing repetitive work, we can help you build a roadmap that delivers results.

To discuss how smart automation could transform your operations, contact Drew Jackson.

Drew Jackson

Manager

Drew partners with our clients to solve complex operational problems and deliver Lean Transformation activity.

View Profile